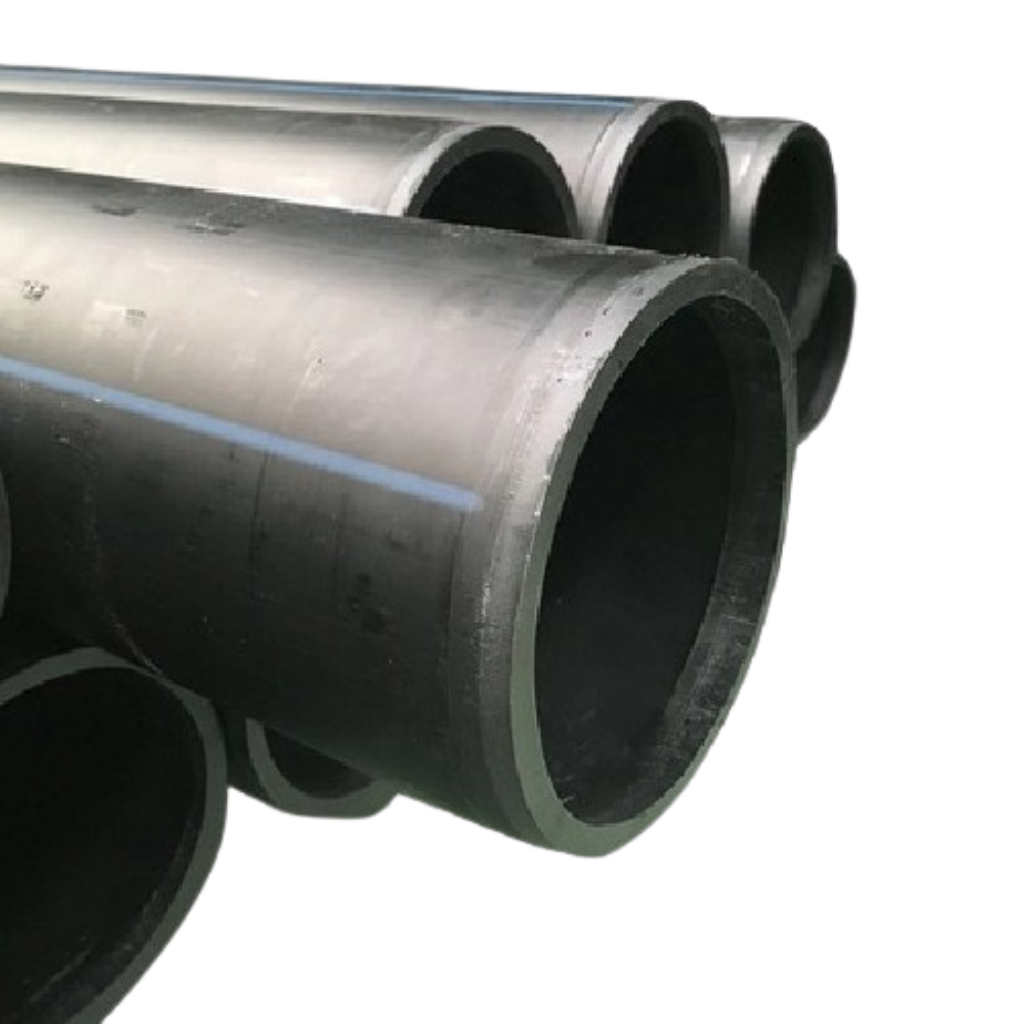

225mm HDPE Pipe

The 225mm HDPE pipe is commonly used in a range of fluid and gas transportation applications, such as municipal water supply, irrigation, industrial processes, and sewage systems. The pipe offers flexibility in pressure ratings, making it adaptable to low, medium, and high-pressure systems. Here’s an in-depth look at the 225mm HDPE pipe, including its pressure ratings, specifications, and common uses.

Explanation of Pressure Ratings

4 kg/cm²: Low-pressure applications, such as irrigation or non-potable water systems.

6-10 kg/cm²: Standard range for most municipal and industrial water distribution systems.

12.5-16 kg/cm²: Suitable for potable water networks, pressurized irrigation, and high-pressure industrial fluid transportation.

20-32 kg/cm²: For very high-pressure systems such as oil and gas transport, chemical industries, and industrial liquid pipelines.

The wall thickness increases with higher pressure ratings, enhancing the pipe’s durability to handle internal pressure.

Wall Thickness and SDR

The Standard Dimension Ratio (SDR) is a ratio that defines the wall thickness in relation to the pipe’s outer diameter. Lower SDR values indicate thicker walls and stronger pipes, which are required for higher pressure ratings.

| SDR Value | Approximate Wall Thickness (for 225mm pipe) |

|---|---|

| SDR 11 | ~ 20.0 mm |

| SDR 17 | ~ 14.0 mm |

Material and Properties

High-Density Polyethylene (HDPE): The 225mm HDPE pipe is made of high-density polyethylene, a thermoplastic polymer with the following key properties:

Corrosion Resistance: HDPE is resistant to corrosion from water, soil, and chemicals, ensuring longevity in demanding environments.

Chemical Resistance: HDPE is ideal for applications where the pipe is exposed to corrosive fluids, such as chemical transport pipelines or sewage systems.

Durability: HDPE pipes have a life expectancy of 50-100 years, making them cost-effective in the long term.

Flexibility: HDPE pipes are flexible, which makes them less prone to cracking under pressure or ground movements.