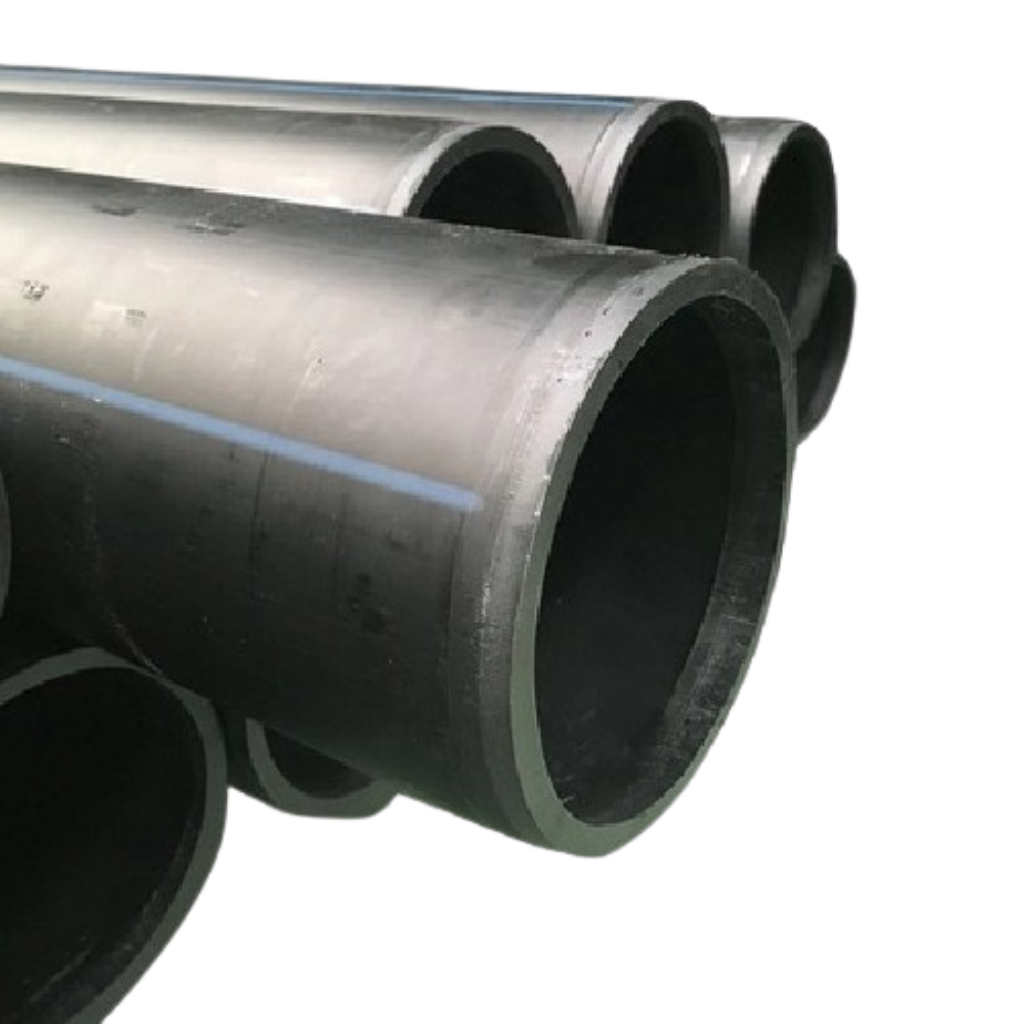

140mm HDPE Pipe

The 140mm HDPE (High-Density Polyethylene) pipe is commonly used in various industries for transporting fluids like water, gas, and chemicals, as well as in sewage systems, irrigation, and drainage applications. Here’s a breakdown of the details you might be looking for:

Material Composition and Properties:

High-Density Polyethylene (HDPE) is a thermoplastic polymer made from petroleum. The high-density nature of the material provides the following benefits:

Strength-to-weight ratio: HDPE is both strong and lightweight, making it easy to handle and transport.

Chemical resistance: It resists a wide range of chemicals (alkalis, acids, salts, and organic solvents), making it ideal for transporting chemicals, industrial fluids, and potable water.

Low friction: HDPE pipes have smooth internal surfaces that reduce friction loss, enhancing flow capacity and energy efficiency.

Non-toxic: HDPE is food-safe, which is why it’s commonly used for water and gas pipelines.

Environmental Resistance

Temperature Resistance: HDPE pipes can generally withstand temperatures ranging from -40°C to 60°C. However, extreme temperatures may weaken the material or reduce its lifespan.

UV Protection: When exposed to sunlight, HDPE pipes can degrade due to UV radiation. To prevent this, UV stabilizers are often added, or the pipes can be buried underground. UV-resistant pipes are available for above-ground installations in places with high sun exposure.

Chemical Resistance: HDPE is highly resistant to a broad range of chemicals, including:

Acids (sulfuric acid, hydrochloric acid)

Alkalis (ammonium hydroxide)

Oils and solvents (fuel oils, chlorinated solvents)

Pesticides, fertilizers, and other agricultural chemicals

Cost and Economic Considerations:

Although the initial cost of HDPE may be slightly higher than that of materials like PVC or concrete, the overall lifetime costs are generally lower because of its durability, low maintenance needs, and ease of installation. The total cost of ownership, considering the lifespan and minimal need for repairs, often makes HDPE a more cost-effective solution over time.